Nanhua Instruments | National High-tech Enterprise

Key Interpretation of HJ1237-2021 Motor Vehicle Emission Periodic Inspection Specification

Release time:

2022-05-11 16:16

Source:

4.2.2 The inspection agency shall be equipped with corresponding trenches or other equivalent devices such as lifting devices, and equipped with mobile appearance inspection equipment, which shall have the functions of vehicle information inquiry, inspection item filling, vehicle environmental protection information public data inquiry, photographing and other functions and be able to network real-time data transmission.

Interpretation

Newly built station: the trench needs to be planned before the exhaust emission test; in-service station: if the trench is after the exhaust emission test, prepare to add the trench in the external inspection area; if it is a pure small car inspection station, the lifting device can be used (the weight lifted by the lifting device needs to cover all the inspection models).

7.2 networking verification shall include environmental violations, emission recall records, vehicle terminal networking status and vehicle maintenance records. For vehicles with environmental violations and emission recalls, owners should be reminded to deal with them in a timely manner. For heavy diesel vehicles and gas vehicles that have installed remote emission management vehicle terminals, the network status of the vehicle terminals should be inquired and the communication status should be recorded.

Interpretation

When the appearance inspection of the inspected vehicle is carried out, it is necessary to increase the network inquiry and the inspection of the network status and communication of the vehicle-mounted terminal.

C.3.1 OBD inspection shall be carried out for the following cars

-Light gasoline vehicles produced after July 1, 2011;

-Heavy gasoline vehicles produced after July 1, 2013;

-Light gas vehicles produced after July 1, 2011;

-Heavy gas vehicles produced after January 1, 2018;

-Diesel vehicles produced after January 1, 2018.

Vehicles that do not fall within the above scope and are equipped with OBD system should undergo OBD inspection, but do not judge the results.

4.2.4.1.1 The equipment shall be directly traced to the social public metrological standards by means of verification or calibration according to the relevant national metrological technical specifications to confirm that the equipment can meet the inspection and testing requirements. Exhaust gas analyzer, gas flow analyzer, opaque smoke meter, chassis dynamometer, engine tachometer, thermometer, hygrometer, atmospheric pressure gauge, etc. shall be within the validity period of metrological verification or calibration. For the equipment that has passed the verification or calibration, the key components that affect the measurement accuracy of the equipment shall be replaced or the equipment shall be re-verified or calibrated after major maintenance, and detailed records shall be made.

Interpretation

Establish files for all equipment, manage the measurement certification expiration information of the equipment, and make detailed records of the maintenance of the equipment.

4.2.3.3 The OBD diagnostic instrument shall support but not be limited to reading vehicle OBD information conforming to the following communication protocols: ISO 9141, ISO 13400, ISO 14229, ISO 14230, ISO 15031, ISO 15765, ISO 27145, SAE J1850, SAE J1939, SAE J1979, etc.

4.2.3.4 The OBD diagnostic instrument shall meet the requirements of supporting five baud rate initialization based on ISO 9141 communication protocol, and the requirements of supporting five baud rate initialization and fast initialization at the same time for ISO 14230 communication protocol. The requirements for automatic detection and matching shall be based on the baud rate (250kbps or 500kbps) of CAN(ISO15765 or SAE J1939 or ISO 27145) communication and K-line (ISO 14230) communication.

Interpretation

The OBD diagnostic instrument has added multiple protocol support and adaptive requirements, and the OBD diagnostic instrument needs to be replaced.

4.2.4.1.2 Each set of exhaust pollutant detection system shall be equipped with at least one set of OBD diagnostic instrument and have the function of receiving data transmitted by the OBD diagnostic instrument at the same time.

Interpretation

Each testing line shall be equipped with a set of OBD diagnostic instrument, and it is necessary to check whether the number of OBD diagnostic instruments on the station meets the requirements.

Note: It is necessary to understand the requirements of the local regulatory authorities, whether it is necessary to prepare 2 sets of OBD diagnostic equipment for the mixed detection line of steam and diesel.

4.2.4.2 The exhaust gas analyzer shall meet the following requirements:

B) The provincial competent department of ecological environment may, according to the actual management needs, require the inspection agency to physically isolate the exhaust gas analyzer except the opaque smoke meter for diesel vehicles, and the exhaust gas shall be discharged out of the operation room through the pipeline.

Interpretation

It is necessary to prepare and plan for the physical isolation of the exhaust gas analyzer except for the opaque smoke meter.

4.2.4.2 The exhaust gas analyzer shall meet the following requirements:

d) The length of the sampling pipe of the exhaust analyzer shall be less than 7.5m, the sampling pipe of the opaque smoke meter shall be less than 3.5m, and the sampling pipe shall include sampling probe, sampling pipe, filter, etc.

Interpretation

The length of the sampling tube includes the sampling probe, sampling tube and filter.

The testing station needs to confirm whether the length of the sampling tube meets the standard requirements.

7.1 inspection shall be carried out in the order of network verification, appearance inspection, OBD inspection and exhaust pollutant detection. If the provincial competent department of ecological environment determines to carry out fuel evaporation detection of gasoline vehicles, it shall also carry out fuel evaporation emission control system detection.

Interpretation

According to the requirements of the local authorities, the fuel evaporation detection of gasoline vehicles needs to be equipped with a fuel evaporation emission control system.

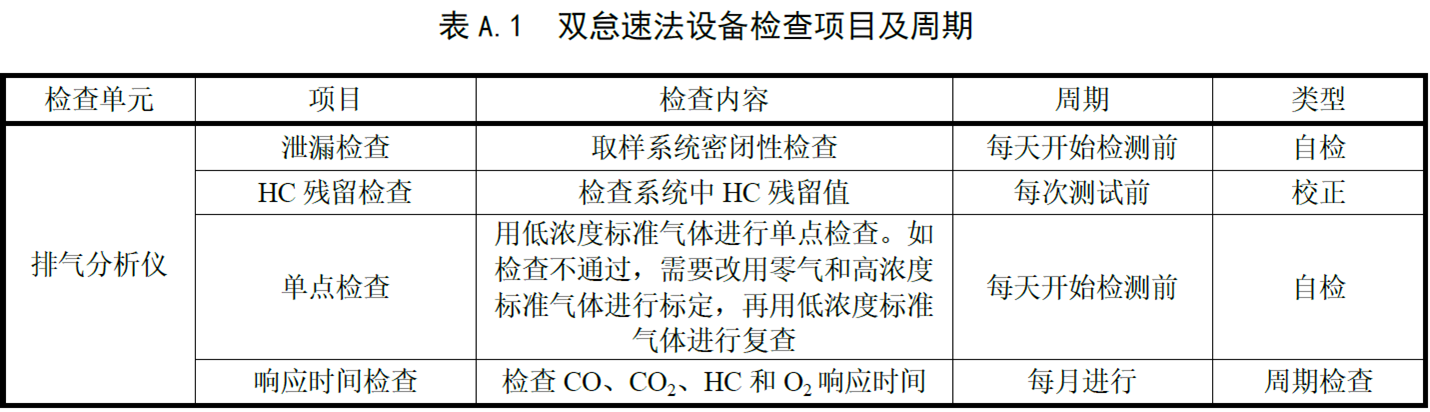

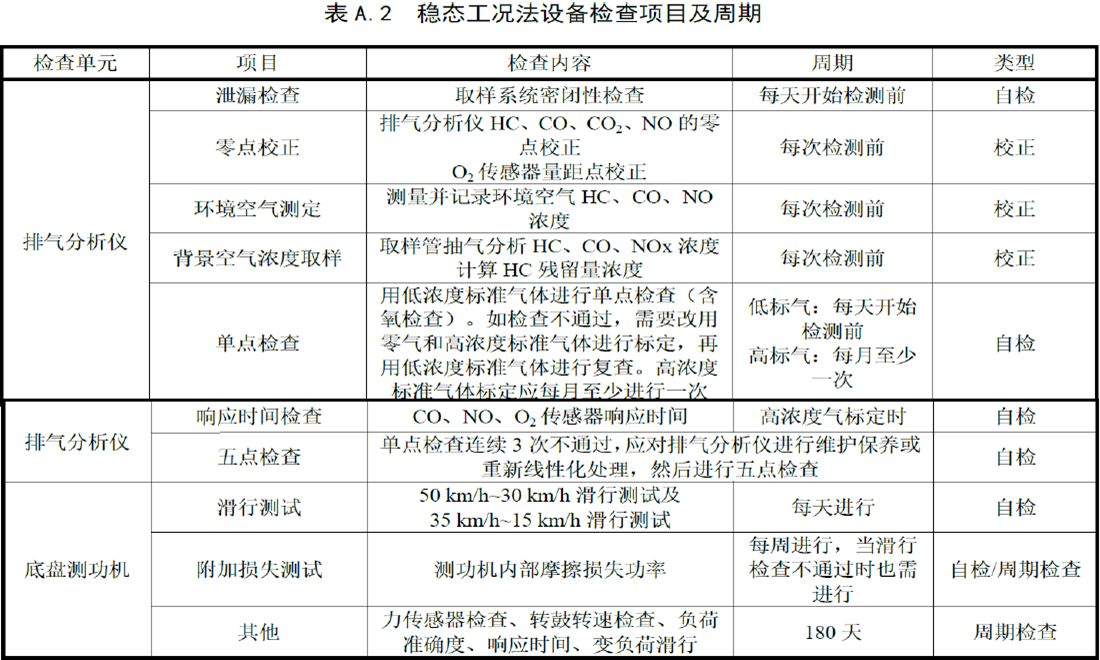

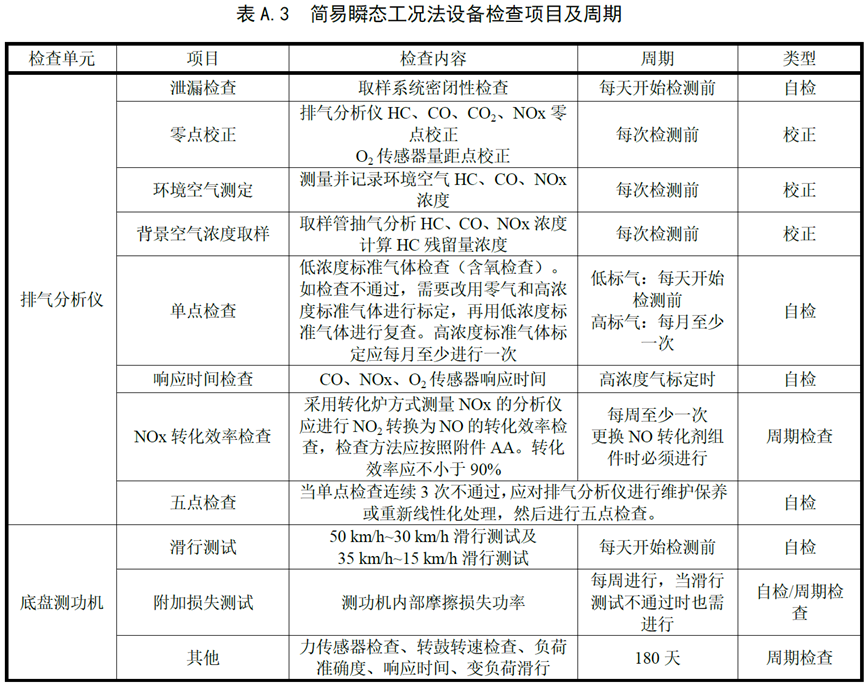

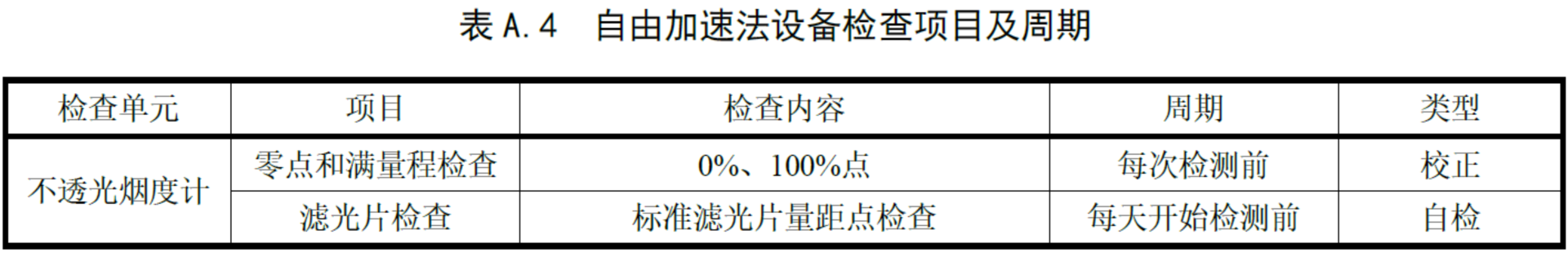

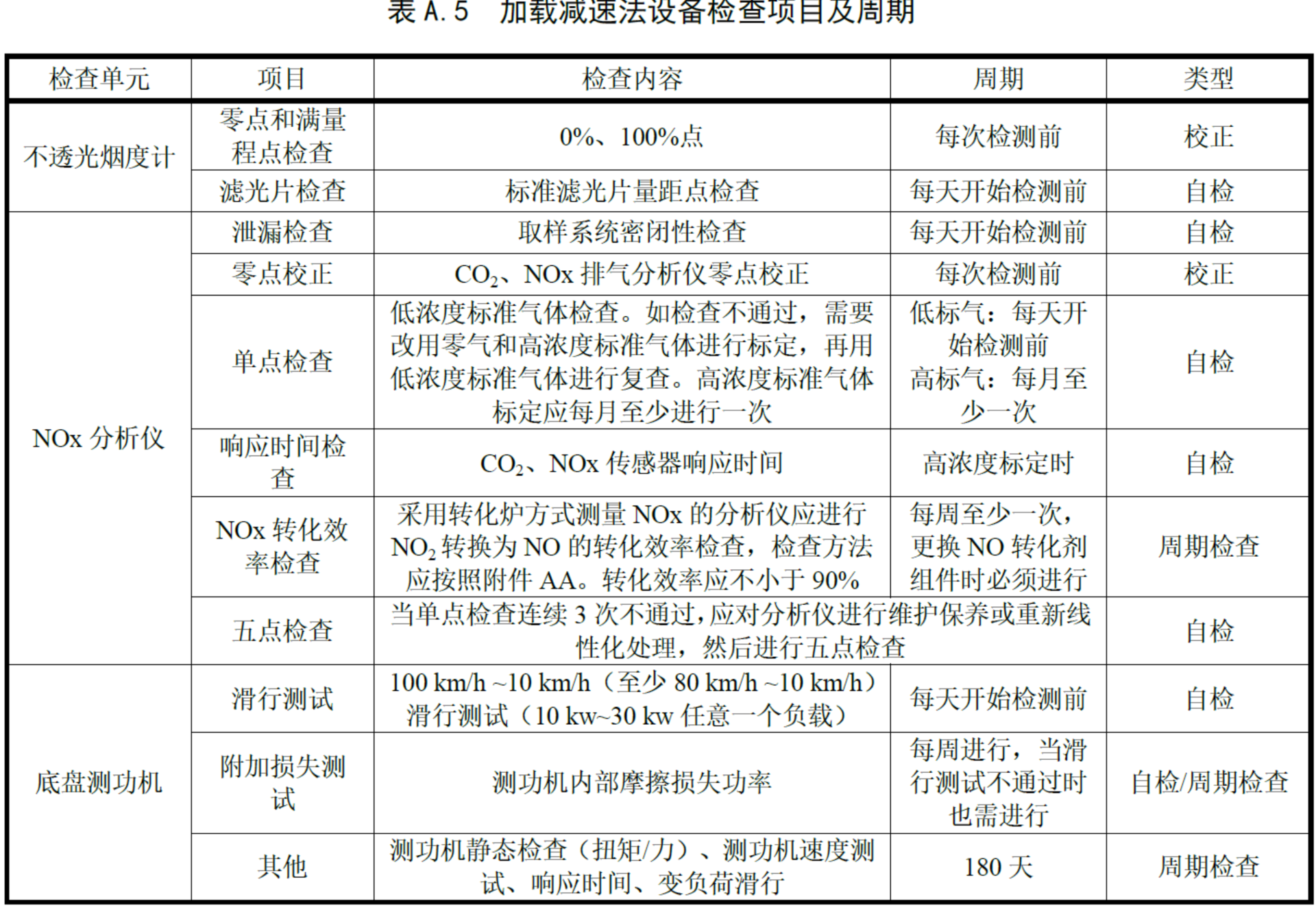

5.1 instruments and equipment shall be inspected regularly as required. If the inspection fails, it shall be locked and unlocked after passing the inspection. Inspection records shall be automatically generated and stored, and transmitted as required. See Appendix A for inspection items and cycle.

5.2 preheating and self-inspection shall be carried out before the first emission inspection every day. If any item fails, the system shall be locked and unlocked after passing the self-test.

5.3 Before each exhaust pollutant test, the exhaust analyzer or opacity meter should be calibrated.

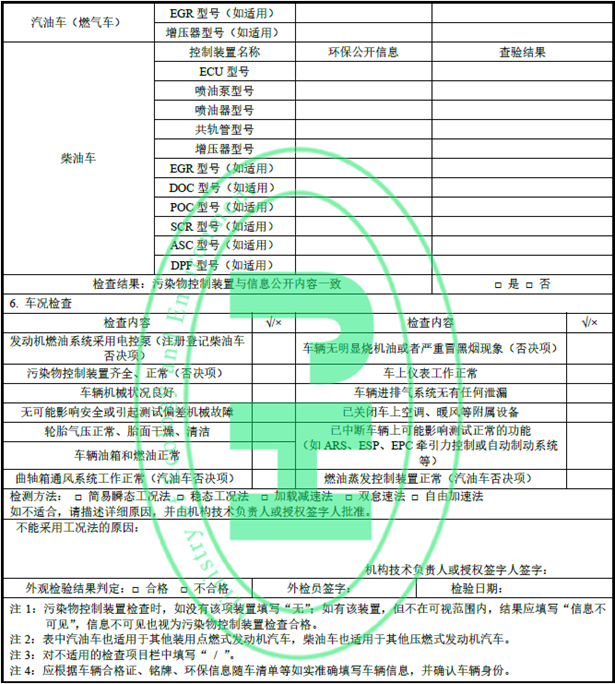

Appendix A

(Normative Appendix)

Equipment Inspection and Calibration Requirements

D.2 Vehicle preheating

For vehicles that are not suitable for measuring the oil temperature through the oil temperature sensor, the engine oil temperature or engine coolant temperature can be read through the OBD. When the temperature data cannot be obtained by the above methods, the exhaust pollutant shall be detected at least 5 minutes after the engine is started, and detailed records shall be made.

Interpretation

Establish a vehicle inspection file to record the preheating situation and reasons before the vehicle inspection that cannot obtain the oil temperature or coolant temperature.

The oil temperature probe is used in the measurement.

D.3.1 If the vehicle cannot be tested by the working condition method due to vehicle technology or safety factors, the inspection institution shall formulate internal approval procedures to record in detail the reasons why the working condition method cannot be used. After the technical director or authorized signatory of the institution signs and approves, the double idle speed method (gasoline vehicle and gas vehicle) or free acceleration method (diesel vehicle) can be used for testing, and the approval records shall be filed with the inspection report. The same vehicle or vehicle of the same model shall adopt the same detection method.

Interpretation

Record the reasons for using simple methods to detect vehicles that cannot be detected by working condition method and approve relevant documents.

The same type of vehicle uses the same detection method.

7.5 If the vehicle emits visible black smoke or blue smoke during the inspection, the appearance inspection shall be determined as unqualified according to GB18285 and GB3847.

D.6 Special Technical Vehicles

For vehicles equipped with two or more exhaust pipes (except for decorative exhaust pipes), or those unable to meet the detection conditions specified in the standard due to special design such as exhaust noise reduction, multi-probe sampling pipes can be used for measurement, or Y-shaped or multi-channel extension pipes can be used to collect the exhaust gas from the same tail pipe, and a single sampling probe can be used for detection. The extension pipe shall be well connected to the exhaust pipe of the vehicle without air leakage, and the length of the extension pipe shall be at least greater than 400mm, which shall have no obvious influence on the exhaust back pressure of the vehicle.

Interpretation

Visible black smoke or blue smoke can be judged to be unqualified in appearance inspection.

For vehicles with multiple exhaust pipes, Y-shaped or multi-way extension pipes need to be prepared.

6.1.1 The standard gas shall have a standard substance certificate in accordance with the relevant national standards and shall be used within the marked validity period.

6.1.2 A reasonable number of standard filters, standard weights for dynamometer calibration and tachometer shall be equipped in accordance with relevant requirements, and metrological verification or calibration shall be carried out as required, and shall be used within the validity period.

Interpretation

Establish the standard material management file, record and save the use change and identification information of standard material.

Verify the data of filter, calibration weight, tachometer and verification validity period (note: the quantity of calibration weight shall cover 80% of the torque range of dynamometer)

Zero point standard gas or zero point standard gas generator conforming to GB 18285 and GB 3847 shall be used for zero point correction of 6.2 exhaust gas analyzer.

The gas composition generated by 6.3 zero standard gas generator shall meet the requirements of zero standard gas in GB 18285 and GB 3847. The zero-point standard gas generator shall pass metrological verification or calibration and be used within the validity period.

Interpretation

It is clear that the zero-point standard gas generator can be used, which needs to pass the measurement verification or calibration and is within the validity period.

The 9.2 inspection institution shall regularly organize the inspection capability verification and comparison test, at least once every six months, and the results and data of each comparison test shall be recorded and archived.

The 9.5 shall establish and improve procedures for complaints and information feedback and handling.

Interpretation

The inspection institution shall conduct the inspection capability verification comparison test at regular intervals, at least once every half a year. Meanwhile, the results and data of the comparison test shall be saved and recorded. The comparison method is not specifically stated here, and inter-station comparison and cross-station comparison will generally be adopted.

Inspection agencies need to improve complaints and feedback handling mechanisms.

Previous Page

Recommend Articles

Nanhua Instruments Co., Ltd.

Add: 1 Kehong, Rd., Guicheng, Nanhai District, Foshan City, Guangdong 528251 CHINA

Tel: +86 757 86718778

Export Dept.

Tel: +86 757 86718629

Email: Export@nanhua.com.cn

Online Message